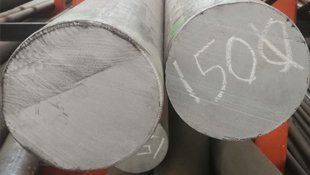

ASIL 1050

Carbon, which is the basic alloying element of steel, affects the hardness and strength properties of steel. In general, it contains between 0.4% and 1.5% carbon element. Increasing the amount of carbon increases the hardness to a certain extent and decreases the weldability of the steel. Examples of usage areas are machinery manufacturing, shafts, gear wheels, bolts and nuts. High carbon steels are also included in the Reclamation Steels group because they are recoverable.

Carbon Steels

They are divided into 3 classes according to the amount of carbon they contain.

Low carbon carbon steels: Carbon steels containing up to 0.20% carbon. Since they have little carbon in their structure, they can be called mild steels. Its properties such as ductility and toughness are high, while its yield and tensile strengths are low. Its hardenability properties are low.

Medium carbon carbon steels: These are carbon steels containing carbon between 0.20-0.60%. They have properties such as moderate yield - tensile strength, ductility and toughness. Since they contain moderate carbon, they have sufficient hardenability properties.

High carbon carbon steels: Carbon steels containing more than 0.60% carbon. They have high yield - tensile strength and low ductility and toughness. Its hardenability properties are quite high. Maximum carbon amounts are usually 1.2-1.4%.

AISI/SAC | DIN | AFNOR | BS |

1020 | C22 | AF42C20 | 070M20 |

1030 | C30 | AF50C30 | 080M32 |

1040 | C40 | XC42HI | 080M40 |

1045 | C45 | XC48 | 070M46 |

1050 | C50 | XC50 | 080M50 |

1060 | C60 | - | 080M60 |

AISI/SAC | DIN | AFNOR | BS |

1020 | C22 | AF42C20 | 070M20 |

1030 | C30 | AF50C30 | 080M32 |

1040 | C40 | XC42HI | 080M40 |

1045 | C45 | XC48 | 070M46 |

1050 | C50 | XC50 | 080M50 |

1060 | C60 | - | 080M60 |